What Is The Product Of Hydrolysis Of An Animal Fat

Introduction

i.1. General remarks

"Animal fats are a by-product of the whole meat chain." While this offset sentence sounds quite simple information technology includes nevertheless two important facts:

- Animal fats are not produced as such. They are only produced in relation to the raising of animals for meat, eggs, milk or wool production. Creature fats are a side, co- or by-product of the production of another beast product.

- The volume of beast fats increases with an increasing production of meat, eggs, milk or wool, but their product won't increase with an increasing demand for animal fats. Animals are not raised for animal fats similar oilseeds are planted for vegetable oil.

Another difference to oilseeds is that, like fish oil production, the processing of beast past-products always includes a thermal processing (melting) footstep; cold processing is non possible.

There are two general categories of animal fats: edible and inedible. Furthermore, the European Union categorised the inedible fats in 3 unlike adventure categories. Some other fat will be included in this affiliate: Used cooking oils (UCO)/Yellow Grease (YG) and Brownish Grease (BG), fifty-fifty though these fats consist mainly of vegetable oils. The collection and treatment of these fats are often in the portfolio of the renderers' business, rather than in that of the vegetable oil producers.

Despite the fact that milk and milk products and fish and fish by-products are also creature by-products, their processing volition exist dealt with in a split chapter.

ane.2. History

The history of rendering can exist approached from dissimilar angles. Since Roman times the fine art of soap making from ash and rendered fat has been well known. Other applications for animal fats, such as candle making from cattle and sheep tallow, came afterward. In the middle of the 19th century the rendering procedure became industrial as well. Rendering in open pans over open up fires evolved into a safer closed vessel system.

Some other aspect was that as cities in Europe grew, a system of expressionless livestock collection and treatment or disposal outside the metropolis walls was established for germ-free reasons. While in the Center Ages skinning of animals for their hides and skins and peradventure the product of baits for wolf hunting was the merely economic benefit for the knacker, rendering fauna by-products for protein and fat now became more attractive than merely disposing of the carcasses. At the terminate of the 19th century this proteinaceous by-product was recognised to be of value as well. First used as a fertiliser, information technology was soon used equally a protein feed chemical compound.

Today it is unclear whether rendering was developed from the rendering of fat and basic from slaughtered or hunted animals or due to the need to handle increasing volumes of dead livestock and slaughter by-products exterior growing cities. But it must exist acknowledged that rendering animal past-products was, is and will exist ane of the most important steps in animal disease prevention. Because animal by-products tend to deteriorate chop-chop since they are a food-rich culture medium for all kind of pathogens, improper treatment leads to severe problems with fauna diseases and zoonoses. The OIE (Office International des Epizooties) acknowledged rendering as the safest, about practical way of expressionless livestock disposal [ane,two].

It tin be concluded that rendering can be seen equally one of the oldest recycling systems in man history. Information technology is fully industrialised today and animal fats and animal proteins are agronomical commodities worldwide.

Brute fats can exist distinguished between edible fats and inedible fats. Not all edible fats are used in man consumption because certain qualities are needed in feed, pet food or the oleochemical industry. On the other mitt inedible fats are not immune in human consumption any more. They can simply be used in feed, pet food, oleochemistry, biodiesel or to generate energy. Edible fats which have already been used in nutrient frying processes, called 'Used Cooking Oils' or 'Yellow Grease', every bit well as the fat stage from the grease trap, the so called 'Brown Grease', are also inedible fats.

i.3. Markets

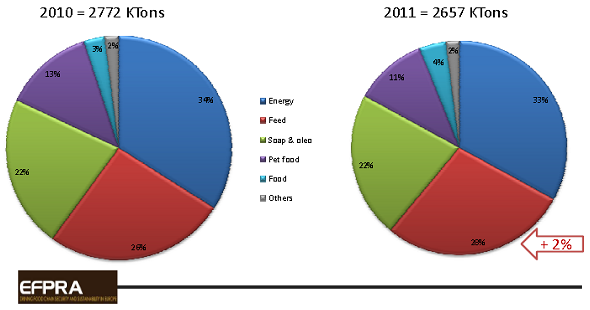

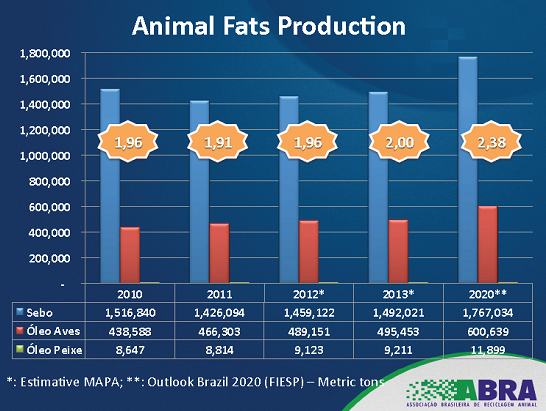

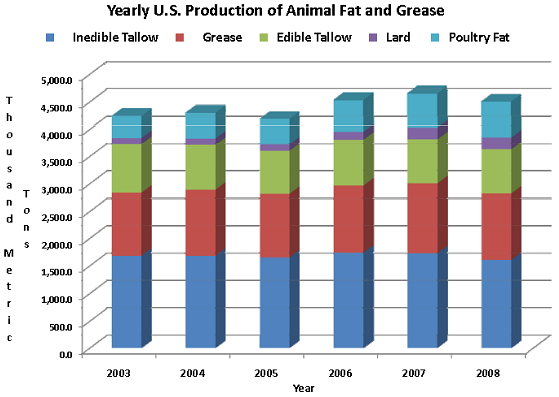

Tabular array 1 and Figures 1-iii show the volumes and usage of brute fat in the key markets of Commonwealth of australia, EU, Brazil and U.s./Canada.

Figure 1. Book and destination of brute fat produced in EU20 (about ii/3 of the free energy uses is defended to biodiesel) [three]. All figures were supplied courtesy of EFPRA.

Figure 2. Product of fauna fat (Sebo), poultry fat (Óleo aves) and fish oil (Óleo peixe) in Brazil [four].

| Table 1. Product of animal fats in Australia in 2011 | ||

| Commodity | Product ('000 tonnes) | |

| Tallow | 487.0 | |

| Poultry oil | 59.vii | |

| Full production - animal fats | 546.7 | |

| Exports | 362.2 | |

| Domestic oleochemical and industrial | 50 | |

| Domestic edible applications | 35.0 | |

| Domestic intensive animal production | twoscore.0 | |

| Domestic aquaculture feeds | eighteen.0 | |

| Domestic pet food | 25.0 | |

| Domestic biodiesel and fuel | 15.0 | |

| Other | i.5 | |

Figure 3. Yearly U.Southward. production of animate being fatty and grease (NRA, www.nationalrenderers.org).

two. Raw materials

2.1. Edible fats

Edible fats are produced from fresh slaughter by-products that were declared fit for human consumption later on a veterinary inspection and are all gained from good for you slaughtered animals. Their production is normally species specific. Typical edible fats are beef tallow, pork lard, goose or duck fat.

Some beef tallow producers subdivide their production even further, e.g. into adipose material from the belly (like kidney fatty) and subcutaneous fatty. Those beef tallows have unlike backdrop because of their different fatty acid composition.

Another edible fat is produced during the gelatin process. Edible gelatin is mainly produced from pork and ruminant bones, pork skins and ruminant hide split. For the gelatin process these raw materials accept to exist defatted. This fatty is hither a co-product of the gelatin industry.

two.2. Inedible fats

The main raw materials are usually slaughter past-products that are fit for man consumption but non destined for human consumption. They come from slaughterhouses and cutting plants and include claret, fats, bones, feet, horns, and innards like lungs, liver, and hearts. They tin can be sold for nutrient but due to changed eating habits especially in the developed countries they may corporeality to well-nigh 50% of the slaughtered animal. Table two shows typical fractions of animal products used in food and not destined for food. This large amount of by-products not going into food, is what slaughterhouses refer to as their "5th quarter".

| Table 2. Average proportion of meat and by-products in different species [six] | ||||

| Slaughtered animal | Human consumption (%) | By-products (%) | ||

| Chicken | 68 | 32 | ||

| Pig | 62 | 38 | ||

| Cow | 54 | 46 | ||

| Sheep/caprine animal | 52 | 48 | ||

Not all animal by-products (ABP) are sent to rendering plants. Meat-rich past-products like lungs, liver and hearts are sold to wet pet food plants. Ruminant hides are used for leather product. Claret is nerveless to produce plasma and haemoglobin fit for man consumption. Pancreas can be used for insulin product, and basic and pork skins are of import sources for gelatin manufacturing.

In developing countries this amount is naturally smaller and includes simply inedible parts of the animal. Inedible by-products include all slaughter past-products which are patently not fit for human consumption like feathers, bristles and horns or cloth that has been declared not fit for man consumption after a veterinary inspection at the slaughterhouse. These are, for example, infected meats, injured animals or legs, meat with haematoma or inflammation.

Inedible by-products also include all animals which happen to die on farms or were culled for animal disease eradication, or animals which are not used for human being consumption, like zoo and circus animals, pets and fur animals. The sanitising process of rendering this dead livestock is a key element in creature disease prevention. The drove and proper heat treatment of all these animals is an obligation in the EU. Elsewhere in the world, it is generally voluntary, i.due east. disposal by composting, land filling, burning etc. is also permitted. Other inedible material is for example eggshells, erstwhile foodstuff/outdated meat and specified risk textile (SRM).

2.2.1. Categorisation of creature by-products in the EU

In 2000, during the height of the BSE crunch in the UK, the European Commission (EC) started to ready up a white newspaper [seven] on nutrient prophylactic. Likewise the foundation of an independent European Food Safety Potency (EFSA), the "farm to fork" approach was ane of the key elements. It should guarantee safe feed for safe food and the on-going eradication of animal diseases and zoonosis. In 2001 the TSE-Regulation [8] was published to eradicate TSE (transmissible spongiform encephalopathy, umbrella term includes all SEs, i.e. likewise bovine as well caprine, ovine, mink etc.). Information technology includes inter alia monitoring programs, definitions of the specified risk materials, the current feed ban of animate being proteins to farmed animals. Simultaneously the EC started its work on an Animate being-Past-Product-Regulation (ABPR) that was finally published on 3.x.2002 [9]. This regulation is directly applicable in all Eu Member States. In 2009/2011 it was revised to Animal by-products Regulation ABPR [ten] and Animal by-products implementing Regulation ABP-IR [11].

The scope of the ABPR is the safe collection, treatment and use of ABP, including full traceability at all stages. If the starting material is food class (edible fatty) and produced in a nutrient plant, the processing weather condition have to comply with food hygiene regulation 852/2004 [12] and specific rules on the hygiene of foodstuffs in regulation 853/2004 [13], even if they are finally sold for other purposes.

A key element of the new ABPR is the definition of ABP: "'beast by-products' means entire bodies or parts of animals, products of animate being origin or other products obtained from animals, which are not intended for man consumption,..". The intention can be "by constabulary", i.east. the material is declared not fit for human consumption or "by conclusion", i.eastward. the material is no longer destined for human consumption. Both intentions are irreversible. One time alleged as ABP the material cannot re-enter the food chain.

The ABPR besides divides the material into three risk-based categories (Table 3). Category 1 is the category with the highest risk of contagion. Heavy metals, persistent organic compounds similar dioxins and PCB, or non-classical diseases similar TSE cannot be sufficiently destroyed by normal rendering and should thus not be recycled into the nutrient and feed chain. Category 2 poses a known and manageable risk of diseases that tin can be reliably reduced past a sterilisation step. Recycling into technical products like fertiliser is immune. Category 3 is the everyman risk category. It includes mainly ABP fit for human consumption (but not destined for human being consumption), and other ABP from healthy slaughtered animals, due east.g. feathers, bristles, horns. Category iii products can be used every bit animal feed (but non for human food!). Catering waste including Used Cooking Oils (UCO) is considered to exist category iii equally well only its utilize in feed is not allowed. With an increasing take a chance there are a decreasing number of different uses allowed. For a cursory overview run into Table iii.

| Table 3. The permitted uses of different categories in the European union | ||||||||||||||||

| Category | Incineration | Combustion | Oleochemistry | Biodiesel | Biogas | Fertiliser | Feed | Pet food | ||||||||

| 1 | X | 10 | Xone | 10 | X2 | |||||||||||

| 2 | X | X | Xone | X | X3 | X3 | ||||||||||

| 3 | X | Ten | Teni | X | Xthree | X3 | X | Ten | ||||||||

| UCO | X | X | X | X | X | |||||||||||

| 1 Only for limited purposes (i.e. no cosmetics, no pharmaceuticals, etc.). | ||||||||||||||||

two.2.two. Used cooking oil/Yellow grease and Brown grease. Another raw textile already mentioned is used cooking oil (UCO), likewise known every bit yellow grease, and trap or dark-brown grease. Despite the fact that both contain mainly vegetable oils and less animal fat, they should be mentioned and explained here, because in many cases renderers handle them, i.due east. deal with collection, cleaning and trading.

-

UCO/Yellow Grease

UCO or Xanthous Grease is the spent vegetable and/or animal fat and oil from deep fryers in canteens, restaurants, fish & chip shops etc. and from deep frying food industries producing products similar meat assurance or potato fries. After the deep frying the UCO is collected separately in bins or tanks, depending on the volumes. Exterior the EU Yellow Grease tin be used every bit feed. Currently it is mainly used for the product of biofuel. -

Brown Grease/Trap Grease

Brownish grease is an emulsion of vegetable and beast oil, fat, grease, solids and h2o. It is separated from the wastewater in a grease interceptor (grease trap) from where information technology can be collected for different purposes. In many countries these interceptors are obligatory for canteens, restaurants, supermarkets etc. Every bit the brown grease is however a water/oil emulsion with an undefined amount of impurities and (normally) loftier free fatty acid content, its utilise is very limited. Some countries allow the use as feed. Other options are to use it as a substrate for biogas or wastewater treatment plants.

The websites of two large American companies, Darling International, Inc. and Sanimax, give good overviews on the service and collection systems.

3. Processing

In general at that place are ii different rendering systems established worldwide. Depending on whether the animate being fatty is gained from an already stale cloth or from a wet phase, the systems are named dry out and wet rendering, respectively. There is no general rule when and where wet or dry rendering is preferred, simply it can exist observed that wet rendering is mostly used where heat-sensitive, high-value products like fish oils, edible fats or poultry fats are produced.

The fat melting and rendering processes aim at three important goals -

- Removal of water to get stable products which are fat and solids, e.thou. proteins

- Separation of the dry product into fatty and solids (protein)

- Sanitation, i.e. the reduction of possible pathogenic loads, which is the less important the fresher the processed material is.

Some of the equipment used in the process is illustrated in Figures 4-seven and 9-ten.

Figure 4. Reception bins.

Effigy v. Breaker.

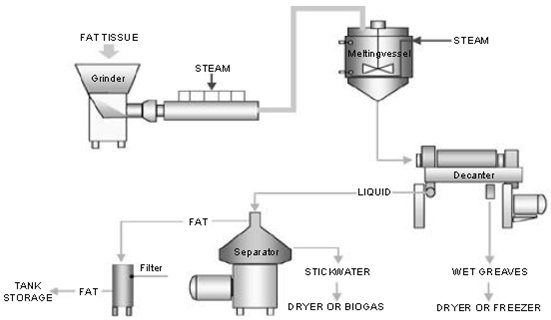

3.1. Wet rendering

Later on size reduction in a crusher (more often than not followed by a mincer), the raw material is melted in a cooker either with direct steam or indirect rut. To avert dissentious the nutritional values, this is carried out at the lowest temperature possible (lxx-xc°C). The separation of the three phases (solids, aqueous phase and melted fat) can be accomplished by dissimilar techniques. The near common is drainage of the solid stage, which is subsequently pressed and stale. The liquid phase is sent to a decanter (horizontal centrifuge) or tricanter. Decanters split two phases, tricanters iii phases in one step. Solids from the decanter are dried together with the other solid stage. The liquid phase, the so-called stick water, is sent to the dryer, either directly or later on a concentration footstep in an evaporation unit. In some cases the liquid phase is full-bodied and stale separately into high-value, highly digestible proteins. The fatty is cleaned.

In food plants the solids from a fat melting establish tin be separated wet from the h2o phase and cooled. The wet cracklings (the unmelted balance later on the fats take been melted) can be sold for human consumption or pet food. Figure eight summarises the process.

Figure half dozen. Cooker / Dryer.

Figure 7. Decanter.

Effigy 8. General menstruum diagram of wet rendering [14].

Moisture rendering is as well used for the pre-processing of material for gelatin manufacturing. Basic, sinews or hide split are defatted with hot water. The defatted products enter the gelatin process and the fatty is separated from the water phase.

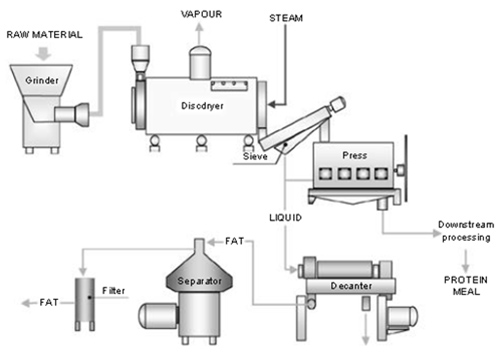

3.two. Dry rendering

After having been crushed, the material is cooked. This process can be continuous or discontinuous. Downstream of the cooker, the processes are mainly continuous. If the cooker does not include the drying stride as well, a dryer volition follow. The cookers and dryers are mainly contact dryers. The 2 main contact dryers are disc dryers and evaporation towers. Sometimes fat is added to the drying step to have a ameliorate heat transfer and to protect the protein quality. The dried material is pressed to yield fatty and solids. Figure 11 summarises the process.

Figure ix. Steriliser/cooker.

Figure 10. Presses.

Figure eleven. General catamenia diagram of dry out rendering [14].

three.3. Milling

The solids are milled into meal afterward a cooling period or active cooling. This process can include a sieve to exclude foreign substances. Some plants use air classifiers to become dissimilar qualities. Table 4 lists the properties of some solids fractions.

| Tabular array 4. Typical qualities of different solids fractions (in weight %) | ||||||||||

| MBM/PAPane | Poultry meal | Greaves repast | Feather meal2 | Blood repasttwo | ||||||

| Protein | 45-65 | 60-68 | fourscore-88 | fourscore-85 | 90-95 | |||||

| Fat | 12-16 | 12-16 | 11-xiii | 7-11 | 1 | |||||

| Ash | 22-35 | ten-20 | three-6 | four-x | 2-three | |||||

| Phosphorus | 3-seven | two-iii | 0.3-1.0 | 0.v | 0.2-1.0 | |||||

| Water | five-7 | four-vii | 4-6 | 6-viii | four-7 | |||||

| one MBM = meat and bone meal; PAP = processed animal protein. two Blood and feathers practice non contain loftier amounts of fat. Their processing does not incorporate a fat separation stride. | ||||||||||

3.4. Water treatment

The h2o is sent to a (municipal) wastewater treatment plant. Many large rendering companies treat their own wastewater because the remaining load (chemical and biological oxygen demand (COD/BOD)) is too high and amounts to besides many population equivalents. For advanced sanitary reasons some renderers decided or are obliged to burn down the evaporated h2o in thermo-oxidisers.

3.five. Fat handling

Brute fat, whether it is produced by wet or dry out rendering, is cleaned in a split up step. Dissimilar methods tin can be used either alone or in combination.

- Sieve

The installation of a sieve is often necessary when a high corporeality of fibres or plastics is expected. Small pieces of plastic in detail are very often a problem in farther uses. The sieve can vary from a rotating screen to a cloth filter. - Sedimentation

This uncomplicated method is very often used. The fat is stored in a tank with a conical lesser where the water phase including solid sediments separates by decantation. The sedimented stage is removed at the bottom. - Decanter

Decanters are horizontal centrifuges that remove water and solids very quickly from the fat phase. - Separator

A separator is a vertical centrifuge. Due to higher speed and the stacked discs, the cleaning results are better than for the decanter. Separators are often used for last polishing of fats later the decanter. The near common is the (cocky-cleaning) disc separator. The application of h2o or acrid solution to improve the cleaning is possible. - Filter

Different filter techniques, e.g. pre-coat filters, can be used to remove solids.

Since the BSE crunch, ruminant fat should be cleaned so that the amount of insoluble impurities does not exceed 0.xv%. Methods are defined past ISO (663:2007) and American Oil Chemists' Guild Official Method (Ca.3a-46, 2009).

Due to the presence of free fatty acids and soaps, brown and yellow grease tin build very stable emulsions and then that it is oftentimes incommunicable to divide a clear fat stage. Therefore, simple techniques like sedimentation and sieving are the almost common techniques for separating h2o and bigger solids from these materials. But yellow grease/UCO of a specified quality is accepted for the product of biofuels, which some producers refine themselves before using it. Brown grease has (due to its poor quality) but limited outlets, e.g. production of biogas, water treatment plants.

The refining of creature fats (bleaching, steam stripping, etc.) as well equally the extraction of fat from meals has already been described in other chapters of the Lipid Library. They are thus not repeated here.

4. Quality

4.1. Quality factors

In improver to the main categories of edible and inedible fatty, different uses crave different qualities. This just ways that dissimilar qualities must be guaranteed for food, feed or fuel uses. The main quality specification parameters tin be presently summarised as follows:

- Water: water content in the fat [%]; a also high water content leads to deterioration, i.e. hydrolysis, complimentary fatty acids.

- Insoluble impurities: impurities left later on a Soxhlet extraction [%].

- Free Fatty Acids (FFA): indicates the degree of hydrolysis [weight % oleic acid].

- Iodine value: The IV indicates the unsaturation of the fatty acids. Fully saturated fats have an 4 = 0.

- Color: should exist characteristic.

- Smell: should exist feature.

- Melting point.

- Smoke point: the temperature at which cooking fat or oil begins to produce blueish smoke. It varies betwixt different fat sources and decreases with increasing FFA.

4.2. Safety

In the past, rendered products were – amongst many others – affected by feed/food scandals. The most well-known are linked to BSE and dioxin. This increased the awareness on nutrient and feed safety and led for example equally a consequence to the implementation of HACCP command systems. It is about important to realise that the processes described do non themselves pb to any contamination. If the raw cloth is already contaminated, there is an inevitable concentration of contaminants in the rendering process simply by the removal of water. The water-soluble contaminants stay in the repast, the fat-soluble in the fatty. Any pollution originates thus from the raw cloth processed.

The production of edible fats has always been subjected to stringent safety systems. The raw material undergoes veterinary inspection at the slaughterhouse and has to be declared fit for homo consumption before the melting procedure.

Long ago animal by-products (ABP) had very often been considered as waste. Some producers accustomed (or did not care well-nigh) the casual mixture with other waste, which was then sorted out by the renderer or by techniques like using metal detectors. Today this has changed. ABP are acknowledged as a by-product with a value which tin can exist maintained past proper handling.

Regarding animal fats, the physical risks are negligible. If we condone the unlikely risks, at that place are the following main risks, which are regularly monitored and controlled:

Chemic risks: As most of the cloth rendered is from animals produced for human consumption, the fat rendered from this material therefore has the same gamble level as regular food. Laboratory animals and zoo, circus and pet animals might receive chemical substances like medications, but the dosage and the fraction of these animals in the total raw fabric stream are normally so low that these substances are both negligible and under the detection limit. Furthermore in many countries these animals are non rendered just disposed of. In the Eu, fat from these animals is simply allowed for very restricted purposes like disposal by incineration, energy production by combustion, biofuel production, etc. Some chemicals, which cannot be digested or excreted, accrue in the fauna's body over the years even if present in the feed in low concentrations. This has been observed for years in studies of different types of meat. Simply thanks to radical reduction of these substances in feed (in view of this aggregating over time), the load in the meat and thus in the ABP as well has been reduced in contempo years.

The following chemical risks can exist identified:

-

Heavy metals are regularly controlled by the nutrient/meat manufacture and by the feed industry as well and so that it is highly unlikely that heavy metals are nowadays. In the past heavy metals were found for example in animals grazing on contaminated land like grasslands flooded by polluted rivers. After the rendering process, heavy metals would remain in the solids.

-

Dioxin, dioxin-like polychlorobiphenyls (PCBs) are regularly checked past the food/meat industry and past the feed industry as well and so that their occurrence is highly unlikely. These Persistent Organic Pollutants (Pop) are emitted by uncontrolled incineration, fires (houses or woods) or volcanic eruptions; therefore, they are ubiquitous. In addition to natural emissions, anthropogenic sources like industry emissions and traffic are the main sources. This means that extensively reared animals are more at risk in industrial areas than intensively reared animals in agricultural areas. As these POPs are fatty soluble they accumulate in the fat. Simply if the meat production is prophylactic, the fatty is not at hazard. Moreover the fat is regularly monitored.

Biological risks:

-

Microbiological pathogens

All rendering processes are designed to destroy thermophilic pathogens during the sanitation processes. As pathogens are attracted to water, their occurrence in fatty is highly unlikely. -

Transmissible spongiform encephalopathy (TSE)/prions

Showtime of all it must be stated that TSE infections are very rare merely not negligible. Only a few countries reported bovine spongiform encephalopathy (BSE) cases: 19 Eu member states, U.s., Canada, Brazil, Japan, Israel, Liechtenstein and Switzerland. To tackle this illness, the OIE classified countries in three dissimilar take chances categories: Negligible, controlled and undetermined. 49 countries accept today a controlled or negligible risk. Prions are proteins; therefore, they do not appear in the fat but in the solids, the MBM . One measure to eradicate TSE was to reduce the amount of insoluble impurities of fat from ruminants downwardly to 0.xv%. This fat tin can nevertheless exist used in feed, while the use of MBM in the feed of ruminants is forbidden.

4.three. Fat profiles

Depending on the species (e.g. poultry = duck, goose, chicken), unlike feeding methods (eastward.g. intensive or all-encompassing), and the different parts of the animals (e.yard. bone, pare, meat, etc.) the fatty acrid profile tin can vary for the aforementioned product. Table v shows full general properties for some species-specific animal fats.

| Table 5. Backdrop of different animal fats | ||||||||

| C atoms | Beef tallow | Pork lard | Poultry fat | |||||

| Melting point (°C) | twoscore-fifty | 34-44 | 23-40 | |||||

| Iodine value | 25-45 | 45-75 | 65-75 | |||||

| Fatty acid composition | ||||||||

| Myristic acrid | 2-3 | 1-1.5 | 1-1.5 | |||||

| Palmitic acid | sixteen | 24-28 | 24-28 | xx-24 | ||||

| Stearic acid | 18 | xx-24 | xiii-14 | iv-half-dozen | ||||

| Saturated fat acids (%) | 46-55 | 38-43.5 | 25-31.5 | |||||

| Palmitoleic acrid | 16 | 2-3 | 2-3 | v-9 | ||||

| Oleic acid | 18 | 40-43 | 43-47 | 33-44 | ||||

| Linoleic acid | eighteen | 2-4 | 8-11 | eighteen-twenty | ||||

| Linolenic cid | 18 | <i | <1 | one-ii | ||||

| Unsaturated fat acids (%) | 45-51 | 54-62 | 57-75 | |||||

Tabular array 6 gives a brusk overview of how the fatty acid contour can exist different in dissimilar parts of pigs and cattle (own composition of industry information and literature, i.e. [15-17]).

| Tabular array 6. Fatty acrid contour of beef and pork fats | ||||||||

| Species - Type of Fat | Fatty acids [weight %] | |||||||

| (location) | 16:0 | 18:0 | 18:i | 18:2 | ||||

| Beef | ||||||||

| - Subcutaneous | 24.vi | xi.1 | 46.6 | 1.seven | ||||

| - Intramuscular | 24.7 | 18.3 | 42.four | 1.nine | ||||

| - Kidney fat (suet) | 25.0 | 29.2 | 33.5 | 1.5 | ||||

| Pork | ||||||||

| - Dorsum fatty | 24.four | xvi.6 | 44.1 | viii.9 | ||||

| - Belly fat | 25.5 | 16.viii | 41.3 | 8.2 | ||||

| - Intramuscular | 26.0 | 15.4 | 43.0 | 7.iii | ||||

| - Foliage fat | 28.5 | 20.one | 37.2 | 7.3 | ||||

The National Renderers Association (NRA) recognised and divers the following categories:

Pick white grease – A specific grade of mostly pork fat defined by hardness, colour, fat acid content, wet, insolubles, unsaponifiables, and free fat acids.

Edible tallow – Exclusively beefiness, this product is rendered from fat trimmings and bones taken from further processing at a slaughterhouse. The production is of lite colour and low moisture, insolubles, unsaponifiables, and free fatty acids. The tallow may be further refined, polished, and deodorized to go a cooking fat. The pet food manufacture more often than not uses the crude product not shipped under seal, oftentimes referred to equally technical tallow.

Edible – Fats and proteins produced for homo consumption, which are under the inspection and processing standards established by the United states Department of Agronomics, Food and Safe Inspection Service (USDA/FSIS).

Fat products – Tallow and grease.

Feed form animal fat – Also known as "Fatty production, feed grade" is any fatty product which does not run into the definitions for creature fat, vegetable fat or oil, hydrolysed fat or fat ester. It must be sold on its specifications which will include the minimum percentage of total fat acids, the maximum per centum of unsaponifiable matter, the maximum percentage of insoluble impurities, the maximum percent of free fatty acids and wet.

Inedible – Fats and proteins produced for animal, poultry, and fish consumption or for other nonedible uses.

Lard – Edible grease, the process and parameters of which are the same as for edible beef tallow, but with pork as the raw material.

Poultry fat – Animal fatty produced from poultry.

Tallow – Primarily from beef fatty, defined by hardness, moisture, insolubles, unsaponifiables, free fatty acids, fatty acid compositions, and colour with a titer of 40.0°C or higher.

Yellow grease – This material is ordinarily made upward of eatery greases (fats and oils from cooking). Some other source could exist from rendering plants producing lower-quality tallow, fats, and greases.

4.4. Other animal fats

As well the higher up described beast fats, in that location are another fats which do not autumn under the heading "fat melting and rendering", every bit they are gained by other processes.

-

Butterfat/antiseptic butter

Butter is a water-in-oil emulsion resulting from an inversion of the cream, an oil-in-water emulsion. Melting butter produces clarified butter or ghee, which is about entirely butterfat. Butterfat tin be produced from milk from any species. Clarified butter can have different regional names: Samna (Centre East) or Ghee (South Asia). -

Wool fat/wool wax/lanolin

Wool fat can be separated from water used to wash the wool. Despite the nonetheless often used proper name wool fat it is not a "fat" considering it consists of wax. The correct proper noun wool wax should therefore be used. Lanolin may contain paraffin oil and h2o. Its awarding is mostly in pharmaceutics/peel care.

5. Markets

Depending on the quality and safety of the fatty there are dissimilar markets worldwide for animal fats. There are in general 3 different qualities: food grade, feed grade or for technical purposes.

five.i. Nutrient

The most prominent example is the use of beefiness tallow for the production of famous tasty French Fries in Belgium (two frying steps at unlike temperatures). Hard fats like beefiness tallow can be used for high-temperature frying. Some other huge client is the bakery manufacture, as in the use of hard fats for the production of puff pastry. Other uses are in the production of soups or apply as such. For all these uses animal fats are normally refined to remove colour and odour.

5.2. Feed

In animal nutrition, fat is used as an effective energy source since its free energy density is 2.2 times higher than that of carbohydrates. Thus fats are used in feed concentrates and diets where high caloric feeds are needed, e.g. calf or poultry feed. They likewise increment the digestibility of fatty-soluble vitamins and provide essential fatty acids.

The digestibility of fats depends on the melting point and thus the fatty acid chain lengths and the degree of unsaturation. The fatty acrid contour as well influences the fatty acid profile of the fat of the animal raised on information technology. It was reported that the unbalanced employ of corn oil or DDGS (dried distillers grains with solubles) in pork feed causes soft rather than hard back fat which then cannot be used for sure food applications like sausage specialities, e.g. hard smoked sausage/summer sausage.

As calves are very sensitive, refined beef tallow is mostly used in dogie milk replacers. Beef tallow meets the natural needs of calves best. Due to its high content of unsaturated fatty acids, poultry fat is used to replace fish oil in fish feeds. Another important use of poultry fat is petfood where it is not but an free energy source but also a palatability enhancer.

v.3. Oleochemistry

Despite the fact that the oleochemical industry tin can apply technical form fat, it mostly requests high-quality products of food or feed grade. This is due to customers' concerns on the i hand and the very sophisticated processes of splitting, etc., on the other manus. The utilise of animal fats in the oleochemical industry is generally linked to the need for saturated fatty acids (for unsaturated fat acids vegetable oils are used). Thus animal fats compete mainly with palm fat, palm kernel oil and coconut oil. The apply of creature fat in the oleochemical manufacture is high in areas where those alternatives do not abound, i.e. EU, the U.s.a. and Canada, or where beef tallow is cheap, i.e. Brazil and Argentine republic. For oleochemical products the fatty acid limerick every bit such is important, only non where the fatty comes from. The fatty acids are used to produce cosmetics, soaps, lubricants, etc.

v.iv. Biodiesel

Since the belatedly 1990s the production of biodiesel has become more than and more popular in the Eu, later in the Us as well. Biodiesel is only a fatty acid methyl ester and can exist produced from whatsoever oil or fat. Information technology has the same ignition properties equally mineral diesel and can exist blended in all concentrations. This means it tin can exist used directly in diesel cars and trucks. This resulted in the Biodiesel sector beingness the fastest growing single market for fats over the last decades. Afterwards an animated "food or fuel" discussion in the EU, sustainability studies of different biofuels were requested and calculated. In the Renewable Free energy Directive (Cerise), default values of the most common biofuels were given. Biodiesel made from animal fats and UCO has a greenhouse gas emission saving potential of 81%, compared to soy biodiesel (31%) almost 2.5 times higher. This is due to the fact that animal fat is not produced for this purpose but a by-production of the meat chain. Thus the whole upstream chain is non included in this default value. In addition to that excellent value, the European union promotes the product of biofuels from waste and residues. Biodiesel from fats that can merely exist used for technical, nonfeed or food purposes and (category ane, 2 and UCO) count twice towards the biofuel quota.

Compared to the production of biodiesel from vegetable oil, production from animal fatty is more challenging and expensive. This is linked to typical constituents similar salts, phosphorus, sulphur, and plastics, which cannot exist totally removed in a prior footstep [xviii].

Nevertheless, as animal fat is only a by-production of the meat chain, its use for biodiesel is e'er linked to meat production and cannot be increased as such. This means information technology will be only a function of the solution, but indeed a very constructive one. It has too been reported that fats (with a depression melting indicate) or UCO are sometimes used directly in trucks.

v.5. Energy

With the feed ban and the exclusion of some beast products from the feed chain, new markets had to be developed. While at get-go fatty was sent to incineration or steelworks as an free energy substitute, the rendering manufacture adapted their steam-raising boilers to utilize animal fat direct on-site for steam generation. Until the demand for biodiesel emerged, thermal boilers had been the primary outlet for technical fats in the Eu.

In thermal boilers, the burners were exchanged and then that the combustion of gas, mineral oil and fat was possible. Using their own fat made rendering plants energy self-sufficient. Today fat is just used in boilers when the fatty does non run across the quality requirement of the biodiesel industry or when mineral oil and gas are more expensive.

Abbreviations: ABP, fauna past-products; FFA, free fatty acids; MBM, meat and bone repast; OIE, Office International des Epizooties (Globe Organisation for Animal Health); PAP, processed animal poly peptide; TSE, transmissible spongiform encephalopathy; UCO, used cooking oils.

6. Literature

6.i Farther reading:

- world wide web.efpra.eu

- The Source of Essential, High-Quality Products, NRA, Second edition, attainable at:

avails.nationalrenderers.org/north_american_rendering_v2.pdf - darlingii.com/UsedOilRemoval.aspx

- www.sanimax.com/view.php?public/Our_services/Collection_services/Used_cooking_oil_collection

6.2. References

- OIE Advert hoc Group on Carcass Disposal, Paris, vi-9 Nov (world wide web.oie.int/doc/ged/D1110.pdf) (2002).

- Ruminant Carcass Disposal Options for Routine and Catastrophic Bloodshed, Issued Paper 41 (National Renderers Clan, Inc., Alexandria, VA) (2009).

- Coelenbier, P. Overview of the European animal by-products industry. Paper presented at the EFPRA Congress 2012, Dubrovnik, (2012).

- Ferreira, A. The Brazilian production in 2010/xi and projections for 2012, 2013 and 2020. Newspaper presented at the 79th NRA Convention 2012, Laguna Nigel, (2012).

- Rath, J. Rendering issues Australian perspective. Paper presented at the 79th NRA Convention 2012, Laguna Nigel, (2012).

- Kamphues, J. Phosphorus derived from animal past-products - Using not Wasting. Paper presented at EFPRA Congress 2009, Cannes, (2009).

- White paper on food rubber, (COM (1999) 719 final 12.1., Accessible at: ec.europa.eu/dgs/health_consumer/library/pub/pub06_en.pdf.

- Regulation (EC) No 999/2001 of the European Parliament and of the Council of 22 May 2001 laying downward rules for the prevention, command and eradication of certain transmissible spongiform encephalopathies, Official Journal of the European Spousal relationship, L147, 31.five.2001, 1-40, Attainable at: eur-lex.europa.european union/LexUriServ/LexUriServ.practice?uri=OJ:L:2001:147:0001:0040:EN:PDF.

- Regulation (EC) No 1774/2002 of the European Parliament and of the Quango of 3 October 2002 laying downwardly wellness rules concerning brute by-products non intended for human consumption, Official Journal of the European Matrimony, L 273, ten.x.2002, 1-95, Accessible at: eur-lex.europa.eu/LexUriServ/site/en/consleg/2002/R/02002R1774-20060401-en.pdf.

- Regulation (EC) No 1069/2009 of the European Parliament and of the Quango of 21 Oct 2009 laying down health rules as regards animate being by-products and derived roducts not intended for human consumption and repealing Regulation (EC) No 17774/202 (Animal by-products Regulation), Official Periodical of the Eu, L300, 14.11.2009, 1-33, Accessible at: eur-lex.europa.eu/LexUriServ/LexUriServ.exercise?uri=OJ:L:2009:300:0001:0033:EN:PDF.

- Commission Regulation (Eu) No 142/2011 of 25 February 2011 implementing Regulation (EC) No 1069/2009 of the European Parliament and of the Council laying downwardly wellness rules as regards animal by-products and derived products non intended for homo consumption and implementing Council Directive 97/78/EC equally regards certain samples and items exempt from veterinary checks at the border nether that Directive, Official Journal of the European Matrimony, L54, 26.02.2011, 1-254, Accessible at: eur-lex.europa.eu/LexUriServ/LexUriServ.exercise?uri=OJ:L:2011:054:0001:0254:EN:PDF.

- Regulation (EC) No 852/2004 of the European Parliament and of the Council of 29 April 2004 on the hygiene of foodstuffs, Official Journal of the European Matrimony, L139, 30.04.2004, 1-54, Accessible at: eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:Fifty:2004:226:0003:0021:EN:PDF.

- Regulation (EC) No 853 of the European Parliament and of the Council of 29 Apr 2004 laying downwardly specific hygiene rules for food of animal origin, Official Journal of the European Wedlock, L139, xxx.04.2004, 55-205, Accessible at: eur-lex.europa.eu/LexUriServ/LexUriServ.exercise?uri=OJ:L:2004:139:0055:0205:EN:PDF.

- Woodgate, South. and Veen, J. van der The role of fat processing and rendering in the European Union animal product industry. Biotechnol. Agron. Soc. Environ., eight, 283-294 (2004).

- Branscheid, W. Tierische Fette im Dilemma - Die Bilanz eines Rohstoffes. Paper presented at the EFPRA Congress 2006, Munich, (2006).

- Tierernährung. Leitfaden für, Beratung und Praxis (DLG-Verlag, Frankfurt) (1997).

- The Original Recyclers (D.A. Franco and W. Swanson (eds.), Fauna Protein Producers Association, Alexandria, VA) (2013).

- Alm, Yard. Tiger in the tank. Oils & Fats International, 28, 24-29 (2012).

Source: https://lipidlibrary.aocs.org/edible-oil-processing/animal-fats

Posted by: grandepoved1950.blogspot.com

0 Response to "What Is The Product Of Hydrolysis Of An Animal Fat"

Post a Comment